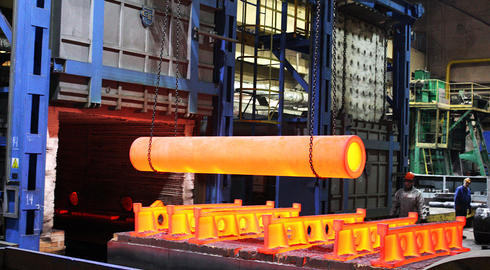

JSC "KMZ" Izhora-Metal" carries out heat treatment of the products made from the following alloys:

Heat treatment is carried out under the supervision of highly qualified specialists, who have extensive practical experience and are able to offer the best technical solutions.

Modernization of heat treatment shop, namely the installation of 7 new heat treatment furnaces with the use of modern refractory materials, advanced burners by Kromschröder (Germany) in combination with Siemens automatics and electronics, allowed to achieve a minimum temperature difference (± 5°C) for heat treatment operations with the heating temperatures up to 1100°C.

| Length, mm | Width, mm | Quenching media |

|---|---|---|

| 4500 | 2500 | water |

| 4500 | 2500 | polymer |

| 2500 | 1200 | oil |

The dimensions of the working spaces of thermal furnaces and the volumes of quenching baths make it possible to form batches with a mass of blanks from 1 kg to 10`000 kg.

| Furnaces | Dimensions, m | Capacity, t |

|---|---|---|

| Gas batch furnace with hearth bottom | 7,0 * 3,5 * 2,1 | 50 max |

| Gas batch furnace with hearth bottom | 7,0 * 3,0 * 2,1 | 50 max |

| Gas batch furnace with hearth bottom | 6,5 * 2,5 * 2,4 | 40 max |

| Gas furnace for the final heat treatment | 6,5 * 2,5 * 2,4 | 40 max |

| Gas batch furnace with hearth bottom | 4,5 * 2,2 * 1,6 | 12 max |

| Gas batch furnace with hearth bottom | 4,0 * 2,0 * 1,6 | 12 max |

| Gas batch furnace with hearth bottom | 4,0 * 1,5 * 1,6 | 15 max |

| Gas batch furnace with hearth bottom | 5,5 * 3,0 * 2,2 | 50 max |

| Electric furnace "NKO 15.20.8/7М" for the final heat treatment | 2,0 * 1,4 * 0,8 | 1 max |

| Electric furnace "SNOL 120/12-I1" for the final heat treatment | 0,7 * 0,4 * 0,4 | 0.03 max |

Appropriate heat treatment is a guarantee of high strength, wear resistance and durability of products.