THE SHOP HISTORY

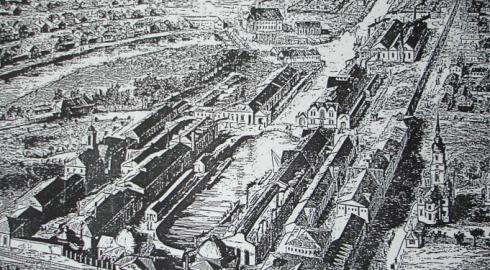

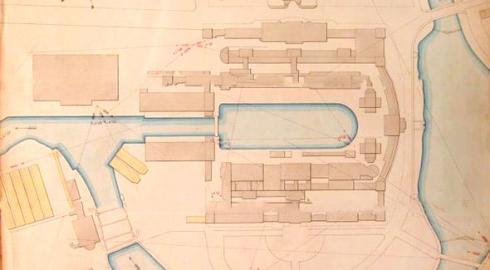

1862 — Creation of a rolling shop as part of the "Admiralty Izhorskiye Zavody" factory

1866 — The first shipboard armor plate was rolled

1870 — At the All-Russia Industrial Exhibition in St. Petersburg, crankshaft forgings made in the rolling shop were exhibited, for which the "Admiralty Izhorskiye Zavody" factory took the first place.

1890-1922 — Production of steam boilers for torpedo boats, being under construction, icebreakers, armor plates for armored cars and armored trains

1923-1942 — Production of forgings for the first Soviet blooming mill

1942 — Production of armored parts for small Navy vessels and armored trains , parts for the "Katyusha" multiple rocket launcher

1953-1958 — Production of forgings for the ECG-8 excavator

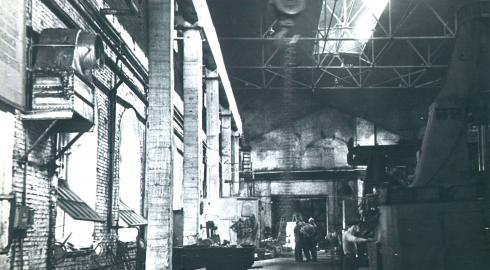

1961 — A forging press with 1250 tons press force was put into operation. Production of forgings for the first in the USSR nuclear reactor VVER-440

1964-1965 — Production of forgings for the ECG-8I excavators

1966-1980 — Production of forgings for the following nuclear power plants: Novovoronezh, Kola, Leningrad, Bilibino, Kozloduy (Bulgaria), Nord (GDR), Loviisa (Finland)

1983-1989 — Production of forgings for the ECG-10 and ECG-15 excavators and for Rolling Mill 5000

1996-2001 — Production of forgings for the following nuclear power plants: Bushehr (Iran), Tianwan (China), Kudankulam (India)

21.10.2002 — Creation of CJSC "KMZ" Izhora-Metal" on the basis of shop number 9. Production of forgings for the prototype of the hydraulic mining shovel EG-5,5

2003-2005 — Carrying out the repairs of 1250 ton forging press. Development and implementation of the technology of forging of alloys Kh16Yu5, Kh23Yu5, Kh20N80; production of forgings from 10Kh11MNAFB and 20KhGSR steels for mining shovels

2006-2009 — Expansion of the range of products, development and implementation of technology for forged rings manufacturing, construction of a compressor station and conversion of equipment from steam to compressed air

2010-2012 — Construction of 7 new heat treatment furnaces for preliminary heat treatment of forgings with a capacity of up to 50 tons with the use of modern refractory materials, advanced burners by Kromschröder (Germany) in combination with Siemens automatics and electronics. Introduction of remote control for overhead cranes. Construction of raw materials section

2013-2014 — Installation of 3 gas furnaces for the final heat treatment with capacity from 12 to 50 tons equipped with Siemens software. Installation of 2 quenching baths with water and polymer quenching medium

2014 — Commissioning of the forging complex consisting of the press CKW630 (ZDAS, Czech Republic) and a 4-ton loader (PHANKE, Germany)

2015 — Conclusion of contracts for the supply of new press-equipment: a 16/20 MN press (SIEMPELKAMP, Germany) and a 10 ton loader (DANGO & DIENENTHAL, Germany)

2018 — Commissioning of the16/20 MN press (SIEMPELKAMP, Germany) and the 10 ton loader (DANGO & DIENENTHAL, Germany)